What is the thermal deformation temperature of PFA tube?

PFA (perfluoroalkoxy resin) pipe has a wide range of long-term use temperatures, and its thermal deformation temperature is usually higher than that of most plastic pipes. The thermal deformation temperature of PFA material is generally about 260℃, below this temperature, PFA tube can maintain stable physical properties and dimensional stability, more than this temperature may occur significant deformation.

What is the hot melt temperature of PFA?

The hot melt temperature or processing temperature of PFA is higher, usually between 350 and 400 ° C, the specific value varies according to different grades and manufacturer process requirements. In this temperature range, PFA materials can be effectively fused, such as extrusion, injection molding and other operations, but need to be strictly controlled to avoid material decomposition or performance degradation.

Can PFA tubes be bent?

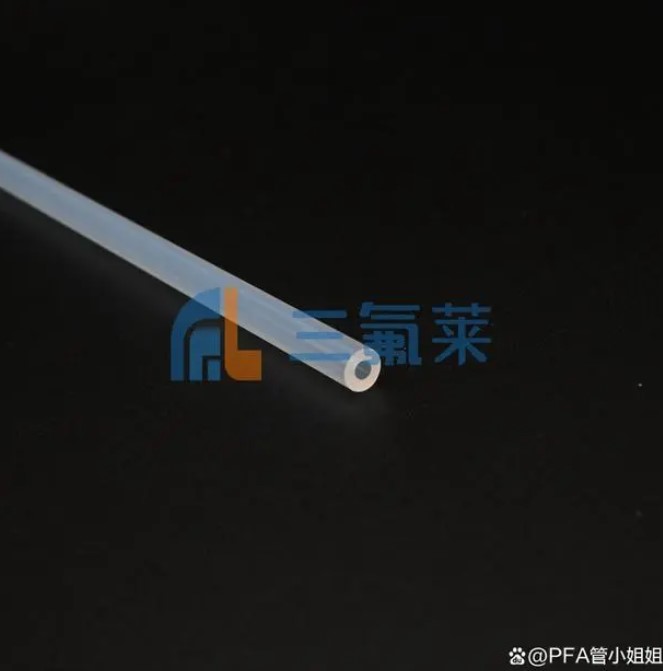

PFA tube can be properly bent due to its excellent flexibility and ductility. Because PFA material has good low temperature toughness and can still maintain a certain degree of flexibility at high temperature, in practical applications, PFA pipe can not only be cold formed at room temperature, but also can be used to make bellows or pipe systems with a certain radius of curvature. As long as the bending radius is large enough during design and installation to prevent internal stress concentration and potential damage due to excessive bending, PFA tubes can be adapted to the needs of a variety of complex layouts and space constraints.

However, although the PFA pipe has good bending properties, the bending operation should follow the corresponding technical specifications to ensure that the pipe wall structure is not damaged, and consider the use environment after bending, such as the possibility of permanent deformation at high temperatures. For particularly complex wiring or connection needs, specialized tools or methods may be required to perform safe and efficient bending operations. At the same time, compared to metal tubes or other rigid materials, PFA tubes may undergo greater elastic deformation when subjected to greater external pressure, which should also be considered in the design.

Sanfulai, high-end fluorine plastic products manufacturer. Supplier of high purity PFA tubes for semiconductor factories.

This article is originally written by Sanfulai. For more information please subscribe to our channel!