What is a semiconductor PFA tube?

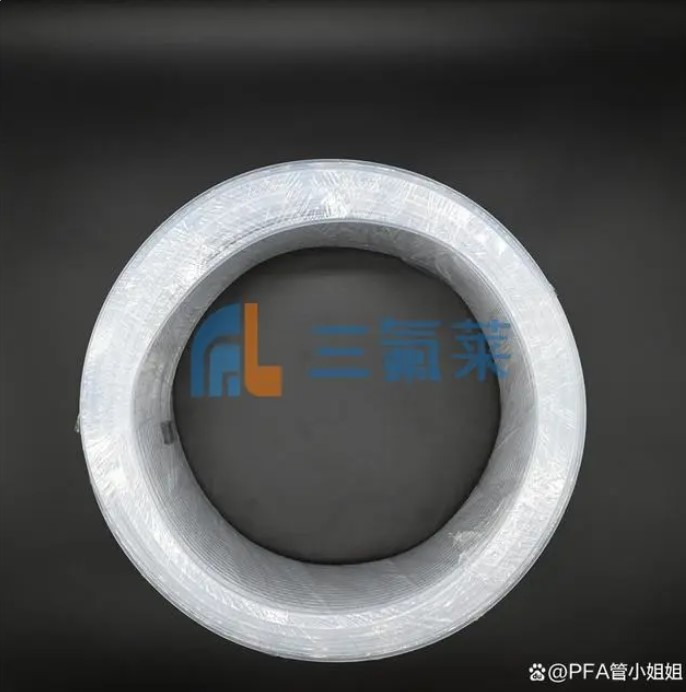

Semiconductor PFA hose is a hose specially designed for semiconductor manufacturing and other environments requiring extremely high purity, and is made of PFA, which is soluble polytetrafluoroethylene. In simple terms, PFA is like a super plastic that can withstand high temperatures, withstand various chemicals, and is very pure. In the semiconductor production process, the purity of the material and the ability to resist chemical corrosion are extremely strict requirements, and the triflurai PFA hose just has these two advantages, so it is widely used in semiconductor manufacturing.

The semiconductor PFA tube has the following characteristics:

High input resistance: The unique design of the PFA tube uses P-type and N-type semiconductor materials to connect the gate and drain, which makes its input resistance far superior to conventional MOSFETs, in other words, it has less impact on the input signal.

Low noise performance: When running, the triflure PFA tube produces very little noise, which means that in the task of processing high-precision signals, it performs quite well.

Energy saving and low consumption: Because the leakage current of PFA tube is small, it consumes low power, which can effectively improve the overall working efficiency of the circuit.

In short, because of these excellent characteristics, PFA tubes have been widely used in various electronic devices such as analog circuits, RF circuits, power amplifiers, switches and oscillators. With the rapid development of science and technology, we expect that in the future, PFA tubes will play a greater role in the fields of communication equipment, computer systems and household appliances, and have a broader application prospect.

What are the applications of PFA tubes in the semiconductor industry?

The wide application of PFA tube materials in the semiconductor industry is based on their excellent chemical stability, high temperature resistance, excellent electrical insulation properties and good mechanical properties. As a versatile material, triflure PFA tubes play an important role in semiconductor equipment manufacturing and processes, ensuring a safe, reliable and efficient production process. With the continuous development of the semiconductor industry, PFA tube materials will continue to play an important role in this field, providing solid support for the realization of innovative technologies.

In the semiconductor manufacturing process, the requirement for electronic chemical purity is increasing as the node size is reduced to 7nm and even 5nm. In the integrated circuit production process, such as wet etching, chemical mechanical polishing (CMP) and other processes, any small impurities can lead to product quality problems, so the purity of the container, pipeline and reaction environment in contact with chemicals is extremely strict.

Due to its excellent chemical resistance, PFA fluorine resin can remain stable in extreme environments such as high temperature and strong acid and alkali, and does not react with solvents, becoming an ideal storage container and transportation pipeline material in the semiconductor industry, effectively preventing the pollution of high-purity electronic chemicals, and helping to reduce the wafer defect rate.

In the chemical distribution system (BCD), PFA is widely used to make components such as ventilation pipes, valves, sinks, etc., to ensure accurate and pollution-free distribution and disposal of chemicals. During the wet etching and cleaning phase, tools such as flowmeters made of PFA ensure the purity of the etching and cleaning fluids and maintain the efficiency of the production process.

During chemical-mechanical polishing, the PFA filter can effectively block large particles of impurities in the grinding fluid to avoid defects on the wafer surface. In addition, because of its good melting processing performance, PFA can be made into wafer supports to meet the needs of various wet processes.

In short, PFA tubes play a key role in semiconductor equipment manufacturing and production processes by virtue of their outstanding chemical stability, high temperature resistance, excellent electrical insulation and mechanical properties, which effectively ensure the safety, reliability and efficiency of production. As the semiconductor industry continues to evolve, PFA materials will continue to play an important role in providing a solid foundation for the advancement of cutting-edge technologies.

Sanfulai, high-end fluorine plastic products manufacturer. Supplier of high purity PFA tubes for semiconductor factories.

This article is originally written by Sanfulai. For more information please subscribe to our channel!