What material is PFA?

PFA, full name Perfluoroalkoxy Alkane, is a kind of high performance fluoroplastic, belonging to the modified material of polytetrafluoroethylene which can be melted. Its main component is a perfluoroalkoxy resin, which provides better fluidity and processability by introducing a specific side chain into the PTFE molecular chain. PFA retains all the excellent properties of PTFE, such as excellent chemical stability, resistance to high and low temperatures, low coefficient of friction and good electrical insulation, and can withstand a wider temperature range and provide greater transparency and mechanical strength. Because of these characteristics, PFA is widely used in semiconductor manufacturing, chemical, pharmaceutical, food processing and other fields, often used in the manufacture of pipes, valves, containers, wire and cable sheathing.

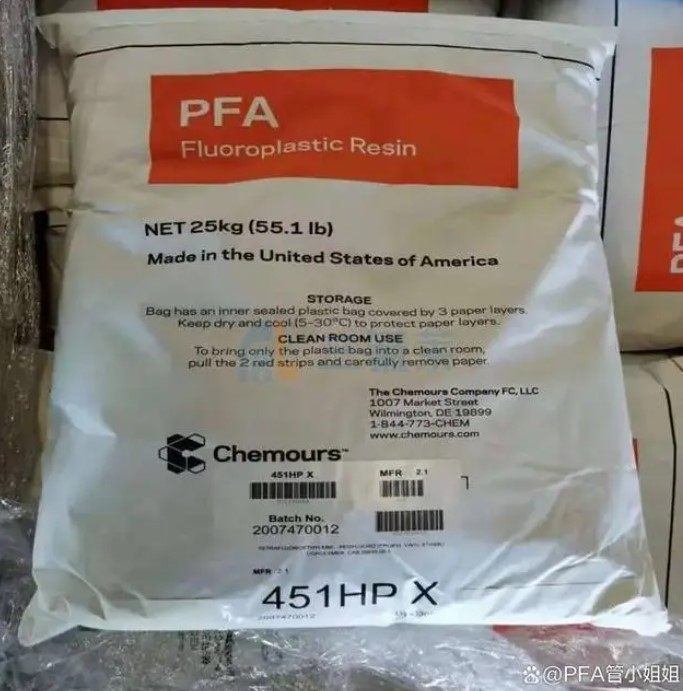

PFA brand mainly for what series?

The PFA grades commonly used by Triflay are generally divided into two main series, the DuPont Teflon PFA in the United States and the Daikin PFA in Japan.

Dupont Teflon PFA mainly has two series of 451HP and 951HP PIus, of which HP is a high-purity grade model and HP Plus is a super-purity grade model. The _PFA raw materials produced by Daikin mainly include AP-211SH, AP-230, AP-231SH and other models, and the models with SH belong to high purity grade, also known as semiconductor grade. Among them, Daikin AP-230 and Daikin AP-231SH are mainly used to produce high-purity PFA tubes for semiconductor manufacturing and photovoltaic, and Daikin AP-211SH is mainly used to produce PFA connectors.

What are the general types of high purity PFA?

High-purity PFA usually refers to specialty materials used in the semiconductor industry, biomedical research, and other areas where purity is highly required. Depending on the application needs, trifluride high purity PFA can be subdivided into different grades or categories, such as:

Ultra-clean PFA: very low impurity content, almost free of metal ions and other particles that may affect purity, suitable for ultra-clean fluid transmission systems.

Electronic Grade PFA: Designed for the electronics industry to meet strict particle control and electrical performance requirements, used as an internal component of precision equipment.

Pharmaceutical grade PFA: in line with GMP standards, non-toxic, tasteless, no adsorption of drug ingredients, suitable for biomedical laboratory equipment and production equipment.

What are the levels of PFA management?

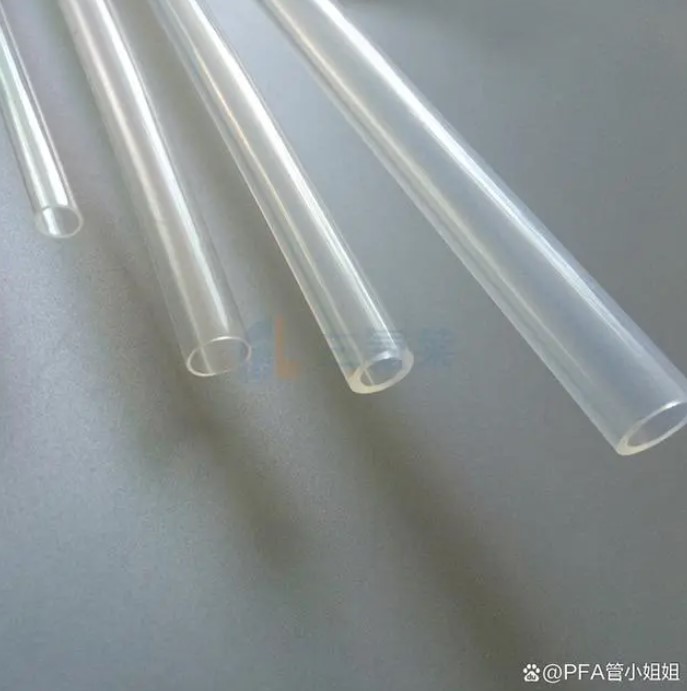

PFA tubes can be divided into various grades according to different production standards, quality requirements and application areas. Common grades of trifluride include, but are not limited to:

Universal PFA pipe: suitable for chemical conveying and heat exchange system in conventional environment, with good corrosion resistance and temperature resistance.

High purity PFA tube: As mentioned earlier, this grade of PFA tube is specially treated to ensure a very low impurity content, mainly used in semiconductor, biotechnology and other industries.

Enhanced PFA pipe: some reinforcers may be added to improve the compressive strength and wear resistance of the pipe, which is suitable for high pressure or severe wear occasions.

Customized PFA tubes: PFA tubes produced according to the special requirements of customers may involve special size, structure or additives to adapt to the needs of specific processes.

Sanfulai, high-end fluorine plastic products manufacturer. Supplier of high purity PFA tubes for semiconductor factories、

This article is originally written by Sanfulai. For more information please subscribe to our channel!