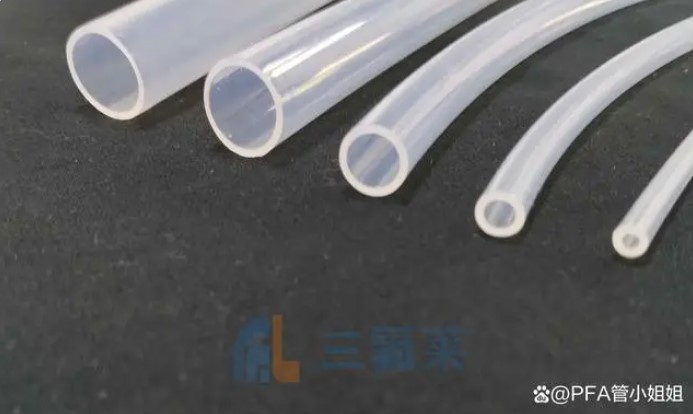

What is a high purity PFA tube?

High purity PFA pipe is a kind of special plastic pipe made of high quality and low impurity polyperfluoroalkoxy resin. In the production process, the purity of raw materials, the processing environment and the process flow are strictly controlled to ensure that there is no dust, metal ions and other pollutants in the final product to meet the requirements of high cleanliness applications. High-purity PFA pipe not only inherits the excellent performance of ordinary PFA pipe, such as high temperature resistance, low temperature, enhanced scientific stability and good electrical insulation, but also its pure characteristics make it irreplaceable in the semiconductor industry, biomedicine, ultra-pure water transportation, high-purity chemical transmission and other fields, which can effectively prevent pollution and maintain the internal cleanliness of the system.

The difference between high purity PFA tube and ordinary PFA tube?

The main differences between high-purity PFA tubes and ordinary PFA tubes are in the production and quality control standards and application areas:

1, production process control: The selection of raw materials in the production process of high-purity PFA pipe is extremely strict, the use of highly purified resin, and the entire manufacturing process is carried out in a clean room environment, strictly limiting the introduction of impurity particles and heavy metal elements, to ensure low precipitation and high stability of the product.

2, impurity content: Compared with ordinary PFA tubes, the impurity content of high-purity PFA tubes is very low, including particles, organic matter, inorganic matter and various elements that may affect the purity of the medium, which are strictly tested and controlled, in line with the ultra-high purity requirements of special industries such as the semiconductor industry.

3, application scenario: Ordinary PFA pipe is widely used in chemical, environmental protection, food processing and other industries, for the basic performance of pipeline materials have high requirements; High-purity PFA tubes are mainly used in industries with extreme requirements for material purity and cleanliness, such as ultra-clean fluid transport systems in semiconductor chip manufacturing, trace analysis equipment in scientific research experiments, and clean fluid handling pipelines in pharmaceutical and biotechnology fields.

Which PFA material grades are commonly used in high purity PFA tubes?

The following are several high purity PFA materials commonly used by Sanfulai:

1, Japan Daikin AP-230: This is a superior performance of PFA material, from the Japanese Daikin company.

2, Daikin AP-231SH: Also manufactured by Daikin, this PFA material has extremely high purity, especially in bending resistance and stress cracking prevention performance.

3. Dupont 451HP: As the founder of PFA, the 451HP model produced by DuPont is often used by the semiconductor industry and is a high-purity PFA material.

4, DuPont 951HP PLUS: This is a ultra-high purity PFA material developed by DuPont, its permeability resistance is about 60% higher than ordinary PFA, especially designed to prevent chemical penetration, resist stress cracking and maintain surface finish, which is essential to reduce pollution, protect the production process and improve the purity of semiconductor products. The DuPont 951HP plus is mainly used to make semiconductor PFA pipes with purity requirements of parts per billion.

Sanfulai, high-end fluorine plastic products manufacturer. Supplier of high purity PFA tubes for semiconductor factories

This article is originally written by Sanfulai. For more information please subscribe to our channel!